This technology prevents water absorption, and hence no efflorescence, mold or mildew staining on the face of the product. Able to be produced using recycled aggregates and cementites materialsĪdditional benefits of DSM products Latest in per-sealing technology.ĭSM have incorporate the latest innovative per-sealing technology to our products.Manufactured close to construction sites, minimizing fuel requirements for handling and transportation.Materials and ResourcesĭSM Concrete masonry and concrete landscape products. Pest resistanceĬoncrete does not provide a feeding ground for pests and termites and it is less likely that termites, ants and rodents will invade your home. DurabilityĬoncrete masonry structures are designed to exceed the required strength for the design strength load. Weather resistanceĬoncrete provides strength and durability to withstand volatile weather including hurricanes, tornadoes, earthquakes, and floods. To reduce waste, concrete block is produced in the quantities needed for each project and can be recycled.

Concrete can also be made with a variety of waste by-products from power plants, steel mills, and other manufacturing facilities.

Limestone, the most abundant mineral on earth, is the predominant raw material for the cement in concrete. This helps to save on utility bills, thus green house emissions by approximately 30%. Energy efficiencyĬoncrete masonry thermal mass allows it to store energy meaning it stays warmer in the winters and cooler in the summer.

Concrete building products can be more than double or triple the life of other common building materials, making it a natural choice for sustainable home construction. Concrete masonry builds durable, long-lasting structures that will not rust, rot, or burn. Green BuildingĪ comprehensive process of design and construction that employs techniques to minimize adverse environmental impacts and reduce the energy consumption of a building, while contributing to the health and productivity of its occupants.Ĭoncrete masonry is global a popular building product that conforms and with the correct design and choice of supplier exceeds the minimum international standards.įrom raw material production to demolition, concrete is a friend of the environment in all stages of its life span. A common metric for green buildings is the LEED (Leadership in Energy and Environmental Design) certification. The design of our products, services, buildings, or experiences that are sensitive to environmental issues and achieve greater efficiency and effectiveness in terms of energy and materials. We allowing for plaster and painting on the internal walls, this is not necessary however as our products have an tractive smooth finish. We did a comparative c ost comparison, analyzing materials available in the Gauteng market. In brief, a wall constructed single skin,no plastering and painting, one operation.

No costly, hazardous painting during construction or in the future will be required, saving costs and the environment from harmful toxic paints and detergents. The nanotechnology is incorporated during manufacture of DSM products and becomes an integral part of the products for the lifetime of the structure. This technology prevents water absorption, and hence no efflorescence, mould or mildew staining on the face of the product.

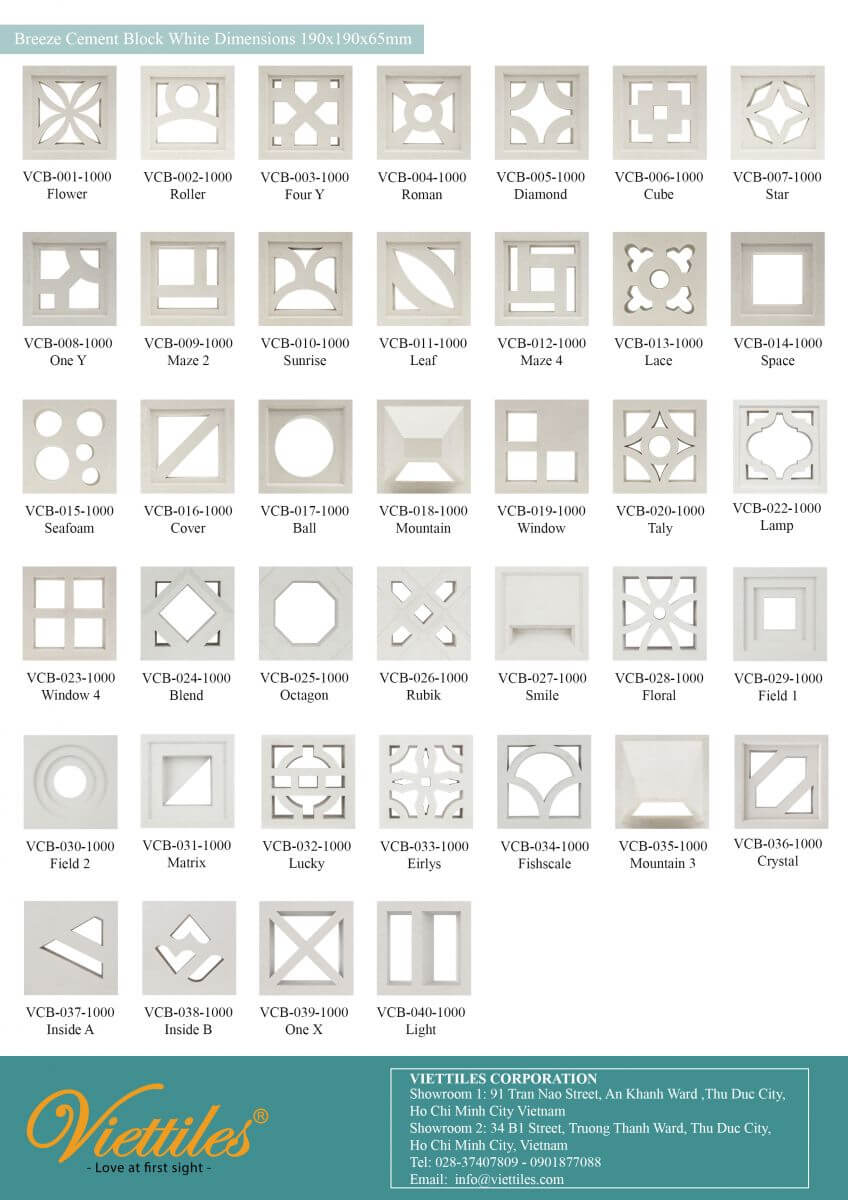

BREEZE BLOCK DIMENSIONS SERIES

DSM have recently introduced a new 150 series to the market.

0 kommentar(er)

0 kommentar(er)